Gloves are one of the most common items of clothing and they have many uses. Gloves ensure a good, stable grip on smooth and wet elements, and can spare the skin on the hands. But gloves can do more than that. There are countless different types that can both protect against sharp objects, blows and/or hot objects. The hands are our most important tool both in private and at work. But there is still a far too large proportion of reported occupational injuries that are related to the hands. This may be due to incorrect gloves being used, or no gloves at all. This guide will help you understand the differences between the many different types and their functions.

YOU CAN CONSIDER THIS:

Before you start, consider the type of work you will be doing and what the task entails. If the work requires you to be in contact with chemicals, choose a glove that can withstand these chemicals. If you go through this list slavishly, it should give you a fair picture of which glove to go for.

- What needs to be worked on?

- Do you have to work with chemicals and/or microorganisms?

- Do you have any kind of allergy?

- What is your need for dexterity?

- Should the glove be exposed to high heat and/or cold?

- Is there a risk of cutting your hand or fingers?

- Do you have specific requirements for comfort?

FIND THE RIGHT GLOVE:

Once you have specified your requirements and considered the above questions, it is time to find the glove that best matches your needs. The most accurate way to select the gloves is based on their approvals and standards. The approvals and standards found in our range are reviewed below. When you have found the approval that matches your glove needs, you can easily and simply sort the gloves on our website, simply by using the "approvals" filters.

LABELING OF GLOVES:

In this section, we review the markings that may be printed on the glove, so that you are equipped to read and learn the various markings and pictograms. The label will often be on the back of the hand, and in some cases inside the glove on the washing instructions. In addition to the markings below, gloves that are approved in the minimum category will have a pictogram that shows the standard the glove is approved to. See the section "Standards".

CE

This marking indicates that the glove meets the general requirements for protective gloves cf. EN 420. The pictogram and marking will often look like this:

Category (I, II, III)

Gloves approved in a category will be marked with this. Often it will be seen as one of the following designations:

Cat. (I, II, III)

Cat. (I, II, III)

The test institute's ID number

Gloves that are approved in category III must be continuously tested by an approved testing institute. These gloves must be marked with the test institute's ID number, which consists of four digits. For example: 0121

CATEGORIES, STANDARDS AND APPROVALS:

In this section, we review the common approvals, categories and standards to which a glove can be approved.

Category I - Low risk

Category I gloves should only be used for tasks with a low safety risk. Category I gloves do not require special approvals, but carry the CE mark. Use: Gardening, lifting, warehouse work.

Category II - Medium risk

The gloves in this category are suitable for medium-risk tasks. The gloves must be tested and approved by an independent testing institute according to EN 420 plus one or more standards, such as EN 374 and/or EN 388. The gloves must have a pictogram illustrating the protective function and CE mark.

Application: Lifting tasks with sharp edges and corners, warehouse work in freezers and/or coolers, or other tasks that require more from the glove than simply providing a good grip.

Category III - High risk

In this category there are the gloves which are applicable for work tasks with high risk, this can for example be chemical gloves, heat and cold gloves, or gloves which can resist radiation or micro-organisms. In this category, the gloves must be tested by an independent testing institute, as category II, and continuous quality control must also be carried out. In addition to the pictogram and CE mark, the product must have a 4-digit code that refers to the testing institute.

STANDARDS:

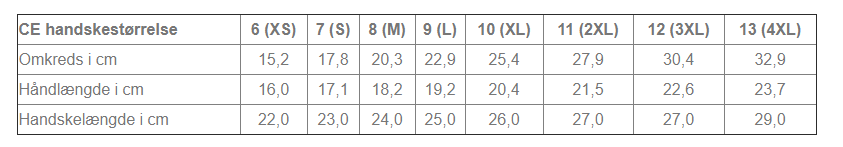

EN 420 - Glove size and basic requirements

All gloves at the Safety Giant are approved and produced in accordance with EN 420, which is a specified basic requirement. These basic requirements include:

- Size standards

- Labeling of gloves and packaging

- pH value: 3.5 < 9.5

- Comfort and finger movement test

- Chromium content (the leather gloves)

- The construction of the gloves

- Documentation

In addition to these usual basic requirements, the gloves are divided into categories that describe the individual properties, which include abrasion resistance, chemical resistance, etc. The categories are determined in EU directive 89/686 EEC, which deals with requirements for personal protective equipment.

EN 388 - Mechanical impact:

This pictogram shows that the glove meets the requirements of EN 388, the four digits indicate the test results.

1 digit = wear roof (1-4)

2 digits = cutting strength (1-5)

3 digits = tear strength (1-4)

4 digits = puncture (1-4)

1 = lowest value

X = Not tested

O = Did not meet the minimum requirements

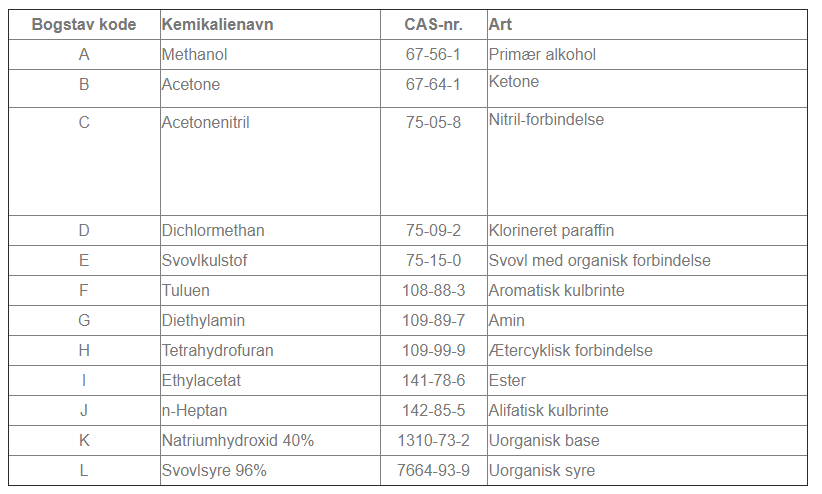

EN 374 - Approved for chemicals

The pictogram shows that the glove meets the requirements according to EN 374. The three letters show that the glove has passed the chemical test.

For complete chemical protection and labeling with a pictogram, the glove must be tested and have passed Pemeation's level 2, on at least 3 out of the 12 listed chemicals. These 3 tested chemicals are mentioned as code letters (AL), which describe which chemical the glove is tested against.

See the chemical list here :

Permeation time

This expresses the time it takes for a chemical to penetrate from the outside to the inside

the glove. The test of the training time must be carried out at 23 degrees +/- 1 degree. Test results are divided into

levels from 1-6:

- Level 1: > 10 min.

- Level 2: > 30 min.

- Level 3: > 60 min.

- Level 4: > 120 min.

- Level 5: > 240 min.

- Level 6: > 480 min.

EN 374-1 - Liquid and air permeability

This pictogram shows that the glove is water and air tight and provides simple chemical protection.

EN 374-2 - Microorganisms

This pictogram shows that the glove is approved as resistant to

training of microorganisms.

The penetration of liquids and/or microorganisms through porous materials, seams, small holes or

other small defects in the glove material. The glove is described as being resistant to microorganisms,

if it lives up to level 2 according to below.

EN 407 - Heat and/or fire

This pictogram carries all gloves that have been tested against thermal risks, heat and/or fire.

The number indicates the result the glove has received in testing. The glove is tested on the following points:

EN 421 - Ionizing radiation

Gloves with this pictogram have been tested and approved as resistant to ionizing radiation.

EN 421 - Radioactive contamination

The glove is tested and approved to withstand radioactive contamination.

EN 511 - Cold

Gloves with this pictogram show that the glove is resistant to cold. The glove has been tested on

following points:

EN 12477 - Welding

This standard is based on a number of other standards and tests. The standard clarifies

the minimum requirements for the results of these tests, in order to be approved as a welding glove according to EN 12477.

To obtain this approval, the glove must be tested for the following:

- EN 388 - Mechanical impact

- EN 407 - Heat and/or fire

- EN 367 - Heat review (related to EN 407)

- EN 702 - Contact heating (related to EN 407)

- EN 348 - Molten metal spatter (related to EN 407)

Welding gloves are approved in two types; Type A and Type B.

The requirements for type A are, in relation to the standards mentioned, higher than type B in most areas.

EN 10819 - Vibration damping

Gloves that are approved to counteract and dampen vibrations are marked with EN 10819.

EN 659 - Fireman's glove

Gloves with this standard are approved for firefighters.

EN 381-4 - Protective gloves, chain saw

Gloves with this approval are approved for working with chain saws.

EN 60903 - Working under voltage

Gloves with this approval are made of a special insulating material which makes

the glove can be used for work under voltage and where there is a risk of electric shock. For

To choose the right glove for the job, it is important to know the tension:

EN 455-1 - Disposable medical gloves, tightness

The gloves are approved for medical use and meet the requirements for tightness.

EN 455-2 - Disposable medical gloves, physical properties

The gloves are approved for medical use.

EN 1149-1 - Electrostatic properties: Surface resistance

The gloves with this approval have been tested in accordance with 1149-1, where the glove's

surface resistance is measured.

EN 1149-2 Electrostatic properties: Through resistance

The gloves with this approval have been tested in accordance with 1149-2. Here the glove material is measured

continuity/electrical resistance.

Symbol Glass/Fork:

The symbol shows that the glove is approved for direct contact with food in accordance with EU regulation 1935/2004.

Glove material:

There is a choice of different glove materials. Some of them are synthetic while others are natural.

All materials have their strengths. In this section, we will review the most common materials that are used for

gloves.

Synthetic glove materials

Synthetic materials are artificially produced materials, such as rubber, plastic, latex, etc. In contrast to

natural materials such as leather.

Butyl rubber:

Butyl rubber has a very high degree of tightness against gases and vapours. The material provides good protection

against many types of aggressive chemicals, such as ketones and strong acids. This material is widely used

extent in the chemical industry.

Chloroprene:

Read under Neoprene.

Dyneema:

An incredibly durable material, made from polyethylene fibres, which is one of the strongest fiber materials out there

exist. Dyneema is up to 15 times stronger than steel, which is why the material is also used in many

product types such as ropes, cables, fishing nets and bulletproof equipment.

Dyneema gloves are particularly used in industry, where high demands are placed on durability, wear and tear.

Dyneema/Fiberglass:

Special blend material that has high performance in connection with cuts and wear. The material is often used

in knitted gloves, where good dexterity and at the same time high protection are required.

Kelvar:

Kelvar is an extremely durable material made from cut-resistant aramid fibres. This means

also that the material and the special weave give the glove a very high cut resistance. Kelvar can too

supplied aluminum coated so that radiant heat is reflected away from the hand. The material's unique properties make that

Kelvar is one of the most preferred materials to produce gloves in, especially when demands are made

the glove for handling hot elements and sharp objects.

Gloves in Kelvar material are washable.

Laminate:

The barrier glove is made of 5-layer laminate, only 0.065 mm thick.

Neoprene:

Neoprene is a synthetic rubber material which is also called chloroprene. Neoprene protects against a broad

range of chemicals, i.a. alcohols, acids and oil products. Furthermore, the material is resistant to

sunlight and ozone. The material is very elastic even in cold environments.

Nitrile:

Nitrile-Butadiene-Rubber (NBR) is a synthetic material that is extremely resistant to boats

mechanical and chemical impact. Gloves as half- and fully-dipped, as well as molded gloves. Molded nitrile

gloves are used in the industry against chemicals, where the dipped gloves are for mechanical wear, e.g. in

the construction industry and the iron and metal industry, where rough items are handled.

Nomex:

Fire retardant material used in the manufacture of fire gloves.

Nylon (Polyamide):

Nylon is used i.a. for knitted gloves where an extra good fit is required. Nylon can be knitted a lot

fine, so that optimal dexterity is achieved.

Polyethylene (PE):

PE is a thin plastic foil material, which i.a. used for disposable gloves with welded edges. Gloves in

this material is suitable for short-term tasks, e.g. when you need to protect yourself from dirt. PE is not suitable for

chemicals.

Polyester:

Polyester is used i.a. for knitted gloves.

PU, Polyurethane:

PU is a synthetic material that is light, soft and very elastic. At the same time, it has good wear resistance.

PU gloves provide good protection against vegetable and animal fat. It is not recommended that one

a PU glove is used if working with water or water-based solutions.

PVA, Polyvinyl alcohol:

PVA is a very durable material that provides a good grip. PVA provides good protection for tasks with

organic solvents, but not suitable for working with water or alcohol.

Vinyl - PVC (Polyvinyl Chloride):

PVC is a strong and flexible material that has been used for many years. The glove ensures a good grip and

maintains flexibility - even in cold environments. The material protects against a number of acids and bases, and is used

within many industries.

Glove Materials - Natural:

Natural materials are all the different types of leather or natural latex and cotton materials which are suitable for glove production. This can be anything from ox, calf or goat skin. See all the different natural materials here.

Cowhide:

Cowhide is the thickest leather that can be used for work gloves. The material is very durable and

tear-resistant, while at the same time providing reasonably good protection against moisture. Gloves in this material are

suitable for all-round work where you want a high-quality glove.

Beef Split:

On the inside of the beef hide is the so-called beef split. Ox split is not as strong as ox house, but

provides better protection against heat. Therefore, this material is often used for welding and heat resistant

gloves. The surface is rough and therefore provides a good grip. Ox split is available in many different qualities and

price ranges.

Pork skin:

This material is more breathable than cowhide, but protects to a lesser extent against moisture. Pigskin gloves

becomes more flexible the longer the gloves are used.

Pork belly:

Pig splits are available in many different qualities and are generally a little less durable than pigskin. Pork belly

used for cheaper types of work gloves.

Goatskin:

Goatskin is a very supple, supple and comfortable type of leather that is thinner than cowhide. This material is

particularly suitable for tasks that require great dexterity, e.g. assembly and precision welding. The material

excellent protection against moisture, as the leather contains natural fat.

Cotton

Cotton is used i.a. for knitted and woven gloves, for example inner gloves, knitted gloves and

drill gloves.

Natural rubber (Latex)

Latex is one of the most elastic glove materials available. The material provides good protection against many

acid and bases, and has a relatively good temperature resistance. Latex is used i.a. in industry, on i.a.

hospitals and the cleaning industry. Latex can cause an allergic reaction in some people.